Challenge

For many Operators, the limiting factor for casing integrity pressure tests is the toe initiation sleeve.

With the depth of high pressure, high temperature (HPHT) well designs, the hydrostatic pressure can limit the maximum applied pressure from surface against the toe initiation sleeves

Solution

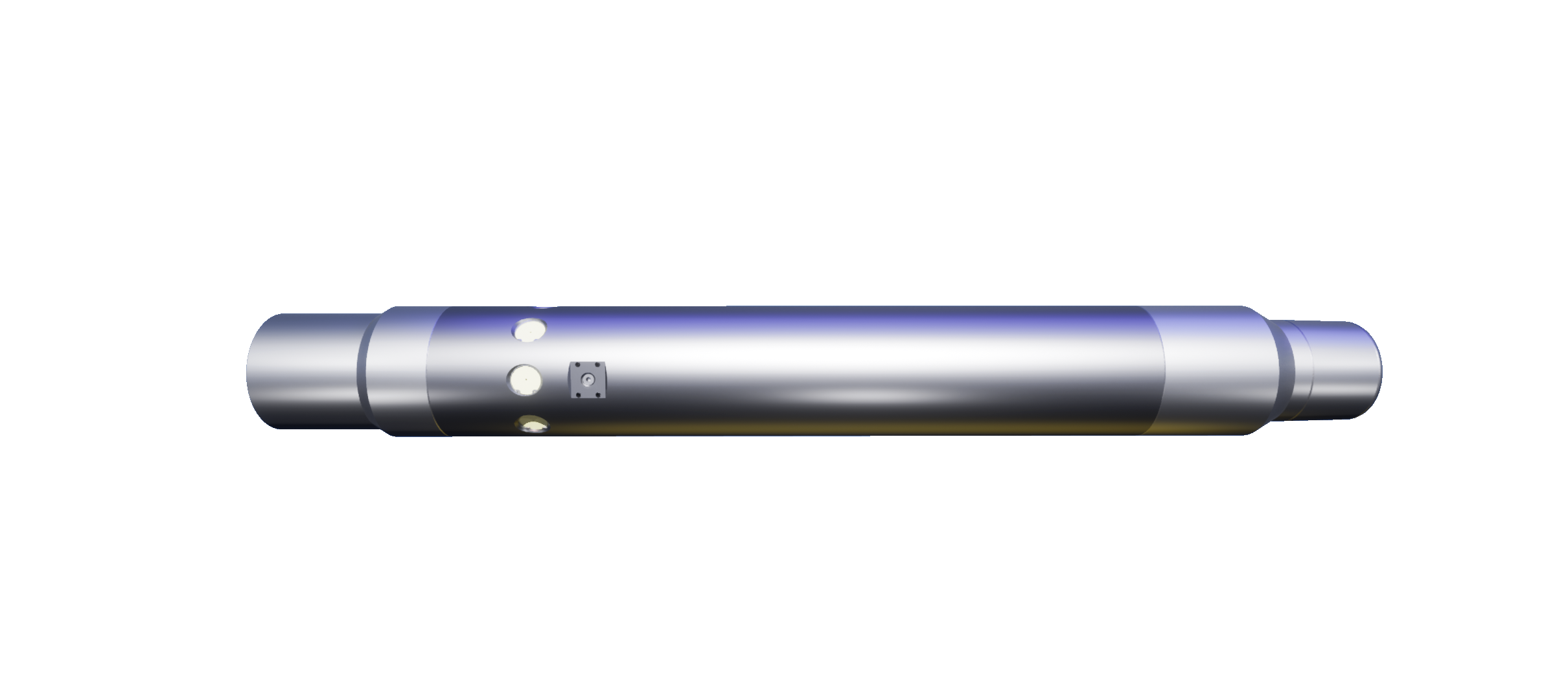

The Howitzer pressure testable toe sleeve design supports higher applied pressure for testing requirements - all ports will independently open on bleed down

Multiple toe ports can be run as a redundancy option

Multiple toe ports in a wellbore reduces the risk of debris (e.g. cement stringers) plugging off the injection ports

Eliminates the need for perforating the first stage of a well

Can be used as the first stimulation stage if desired

Meets all regulatory pressure testing and casing integrity requirements

Results

Running multiple Howitzer toe sleeves is more economical than running other commercial options, and it can also be used as a limited entry frac stage

Savings to customers can exceed greater than $50k per well and 6 – 12 hours of coiled tubing run time

More flow area than competing commercial toe ports

Optional ball seat configuration allows for multiple casing integrity tests